As a specialist for linear positioning systems we develop especially economical, high-quality solutions which are exactly tailored to our customers requirements. We offer a comprehensive range of products including basic linear axes and complex gantry robots. Our modular systems consist of standardised components, 90 per cent of which are manufactured in Germany.

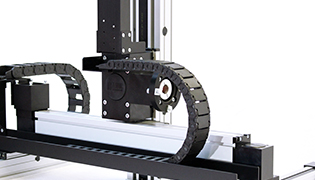

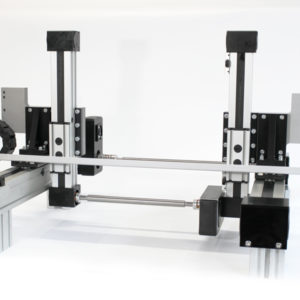

„Since we deliver our positioning equipment in the form of complete assemblies for machine construction, we need absolutely calculable standards“, explains Hartwig Summer, sales director at Bahr Modultechnik. We assemble positioning axes from more than 200 different aluminium profiles in any length up to 60 meters, while it is also possible to cut the profiles „by the meter“ according to the individual requirements. T-slots in the profiles serve as standardised connecting profiles and make it possible to mount gantry axes with any dimensions very quickly. The guide carriages of the positioning units can be moved by belt drives, rack-and-pinion drives, spindle drives, roller guides or alternative customer-specific drive concepts. All our systems are provided with coupling claws for connecting electrical motors and control units of all usual types and can thus be easily integrated into the users’ existing control networks. The clever system simplification and the fact that we only use standardised components contribute to the special cost-effectiveness of our positioning systems. Design, production, sales and logistics are seamlessly integrated within our company, which is a globally recognized partner for manufacturers of special-purpose machines and niche applications. This is because BAHR MODULTECHNIK attaches great significance to individual advice and tailor-made solutions and „develops further with every customer and every application“, Hartwig Summer continues.