LINEAR TECHNOLOGY IN THE DEEP-FREEZE AREA

High reliability and minimum machine downtimes are always essential, in particular for applications with extreme conditions. For example, production and logistics processes with temperatures of up to ‑45 °C require dynamic and precise linear units that meet all your specific challenges.

COLD-RESISTANT LINEAR TECHNOLOGY

In the areas of food production and logistics, a large part of frozen products are stored at temperatures between -40 °C and -20 °C. Regardless of the products being processed, the prescribed minimum temperature in this industrial sector is -18 °C. This value is specified by the HACCP guidelines, which represent an important criterion that must be met. When developing and designing a suitable special-purpose machine, engineers and technicians are thus faced with special challenges.

In order to meet even the most challenging requirements of our customers, we have introduced the NORDKAP product series. With customizable linear axes for deep temperature applications, we ensure the required longevity and quality of your specific application.

KEEP COOL - THANKS TO RELIABLE HANDLING

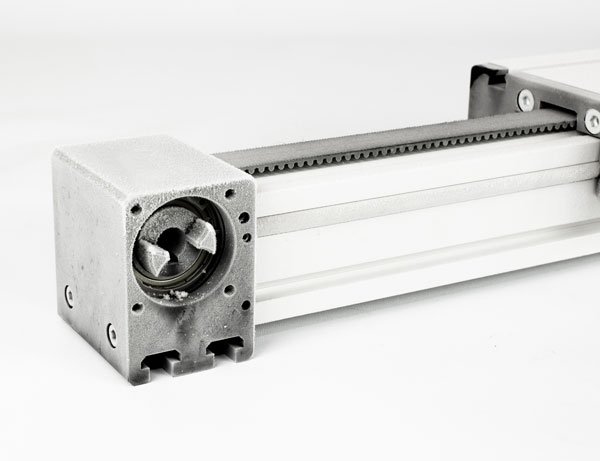

Production losses and long machine downtimes can quickly lead to undesirably high costs, especially for deep-freeze applications. Therefore, maintaining cold chains requires special efficiency and economy with regard to the automation of processing steps. The handling of tools, components and products always has to be performed in a reliable and precise manner. The service life of your application should be maximized, while the maintenance effort should be kept to a minimum. Our new toothed belt drive ELZ-NK ensures your success.

Technical features ELZ-NK

- Highly dynamic linear units with belt drive and individually configurable travel paths

- Unrestricted usability in deep-freeze applications with temperatures between -10 °C and -30 °C (-45 °C possible with limitations)

- Space-saving due to compact design

- Positioning systems in corrosion-protected design available as an option (recommended for alternating climates)

- Customized system design for your particular use case

- Reliable and low-maintenance guide system with robust track roller guide

- Long maintenance intervals with long service life

Do you have any questions?

We will be happy to advise you. Simply contact us via our contact form.