LINEAR AXES FOR 3D PRINTING

3D printing demonstrates your strengths where conventional manufacturing has reached its limits. These manufacturing processes are often used in prototype construction, for components with a high degree of customization, and with complicated geometries. Our linear axes fulfil the requirements of 3D printing machines in terms of precision, dynamism, and operational reliability. Outdo the competition and turn your ideas into reality.

PRECISION AND QUALITY In LAYERED MANUFACTURING

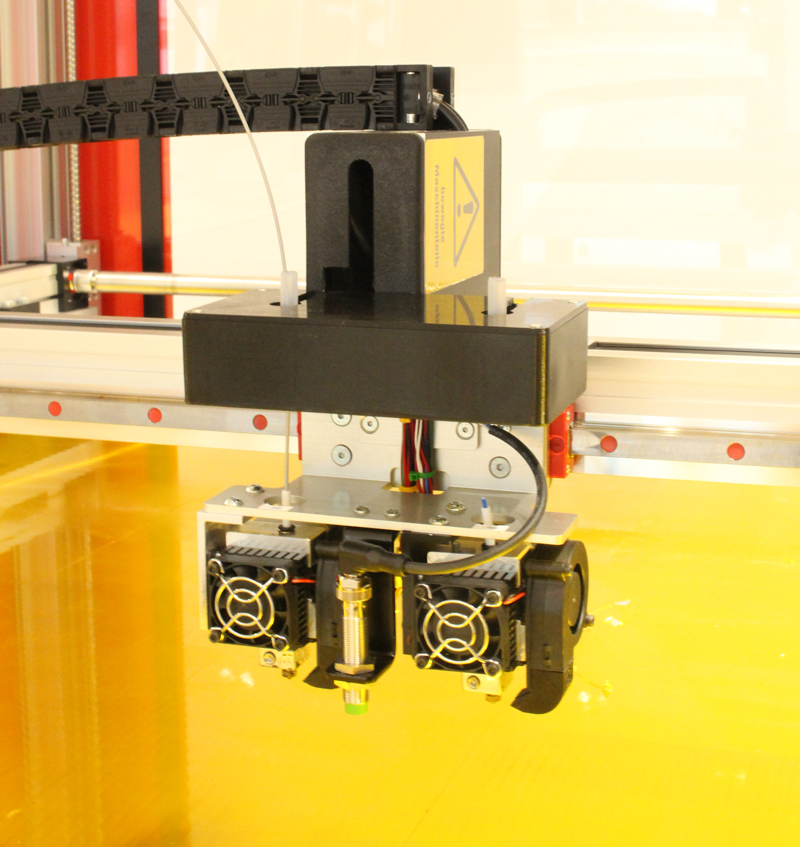

Additive manufacturing is continuing to make headway – and has become a genuine alternative to traditional manufacturing methods. 3D printing with plastic, metal or ceramic powders opens up new possibilities in product design, and clears the way for manufacturing components efficiently in small quantities. Linear axis systems are an essential feature in 3D printers. For example, they position the laser head in the portal group and feed in material layer by layer. Here, Bahr Modultechnik’s linear axes are used in a challenging environment that calls for a high level of positioning and repeat accuracy. Furthermore, the linear systems must achieve a high level of dynamism – and that in non-stop, 24/7 operation. Service life therefore really counts in additive manufacturing, as do operational reliability and drive performance.

PRECISION IS KEY IN ADDITIVE MANUFACTURING

Above all, it is linear axes with spindle drive and nubbed belts, that, with their precision and excellent rolling characteristics, determine quality in 3D printing. Additive manufacturing is used when the limits of conventional processes have been reached. The method is used to produce delicate components from various material powders with layer thicknesses ranging from 0.015 to 0.1 millimeter. Because of these new possibilities, more and more business divisions are employing this technology and discovering the benefits of the new production process. With that in mind, the printer and all peripheral equipment must be as compact as possible. This leads in the realization to custom-designed linear axes that are easy to integrate and that waste no space.

Bahr Modultechnik therefore always builds its linear axes to customer specifications from a modular construction kit. Everything in it is standardized for industrial application – but is freely configurable in the required length and a whole host of other customization options.

Have a look at our product catalog.

Our advantages – For you

Take advantage of the benefits we offer. You get a comprehensive solution, customized to your needs:

- Unlimited individualization

- High speed and acceleration

- Process reliability

- Maximum precision

- Advice and support with outstanding customer service

- Comprehensive product portfolio in premium quality

- Short delivery times within 2–3 weeks

- Emergency service and delivery within 24 hours

- Easy assembly with extensive accessories

„As part of a project, we worked with Bahr Modultechnik to develop a five-axis 3D printer that is driven by Siemens motors and a SINUMERIK.

The collaboration was superb and straightforward throughout the entire project. The expert and personal advice, and the first-class design of the linear technology played a key part in the success of the project.“

All features at a glance

We provide premium-quality linear axes with the following features:

- Low noise and low maintenance

- High precision

- Speeds up to 8 m/s and acceleration up to 10 m/s²

- Space saving thanks to compact design

- Long service life and high load capacity

- Low weight

- Aluminum profile with hardened and anodized surface

- Temperature range -25°C to 85°C

- Resistant to environmental influences (dust or abrasive materials)

Do you have any questions?

We will be happy to advise you. Simply contact us via our contact form.